Students of NSYSU-CSE won champion award in 4th AIoT Innovation Competition with AI motor failure diagnostic platform

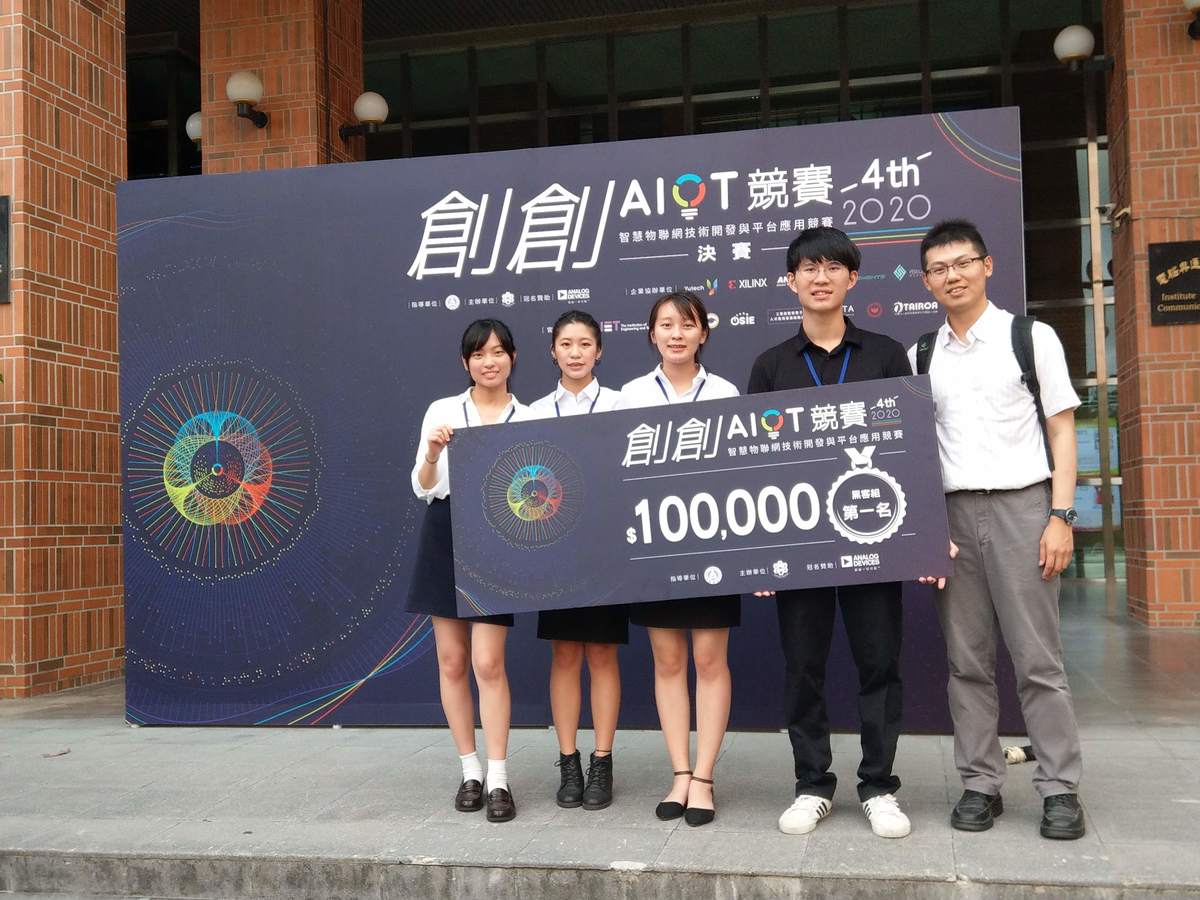

(Report by student journalist) The motor fault diagnosis platform developed by a team of one teacher and 4 students in the Department of Computer Science and Engineering (DCSE) at NSYSU, won the first prize in the hacker group of the 4th AIoT Innovation Competition (第四屆創創AIoT競賽黑客組). The team members said that this platform can be applied to fields related to electric vehicles in the future to effectively reduce the probability of public safety accidents and the external cost of accidents, respond to current needs and bring benefits to society.

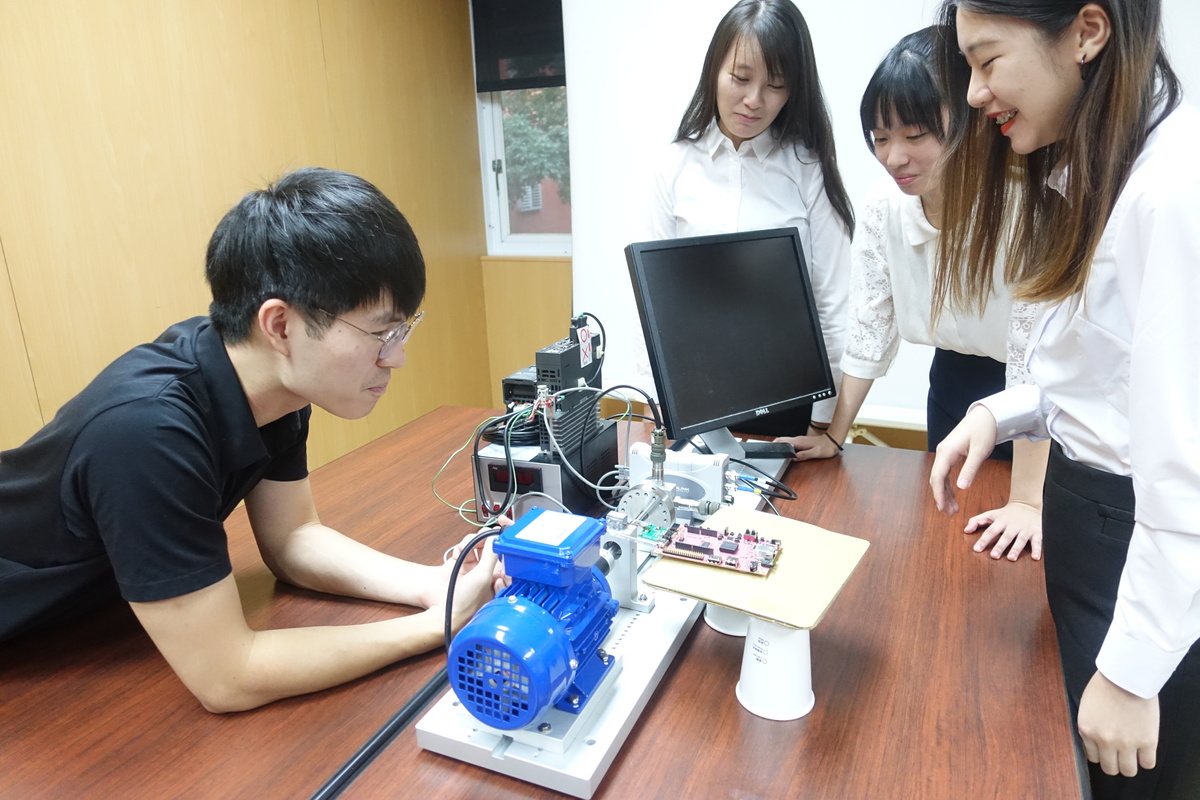

AIoT is the combination of Artificial Intelligence technology and the Internet of Things in practical applications; it is a very popular trend at the moment. Three senior undergraduate students: Jo-Chiao Ku, Hsiang-Ling Tai, Jui-Cheng Wang, and a second-year Master student Jing-Wen Liang, designed the motor bearing fault detection system for the future smart factory under the guidance of Assistant Professor Kun-Chih Chen, and won the review committees’ favor. On the day of the finals, NSYSU students and teacher transported their work to the competition site for data analysis as well as a demonstration. To meet the requirements of this competition, they further designed a program to remove the noise in the acquired signals. The team immersed in their project wholeheartedly and usually stayed in the laboratory until early morning hours to collect data. Jui-Cheng Wang said very humbly that it is very surprising and unbelievable to hear the news of their victory. Jing-Wen Liang confidently mentioned that their developed platform fits in the trends of the modern smart industry. It can be widely used to find the bearing faults through signal collection and analysis, which will efficiently help the factory save labor expenses.

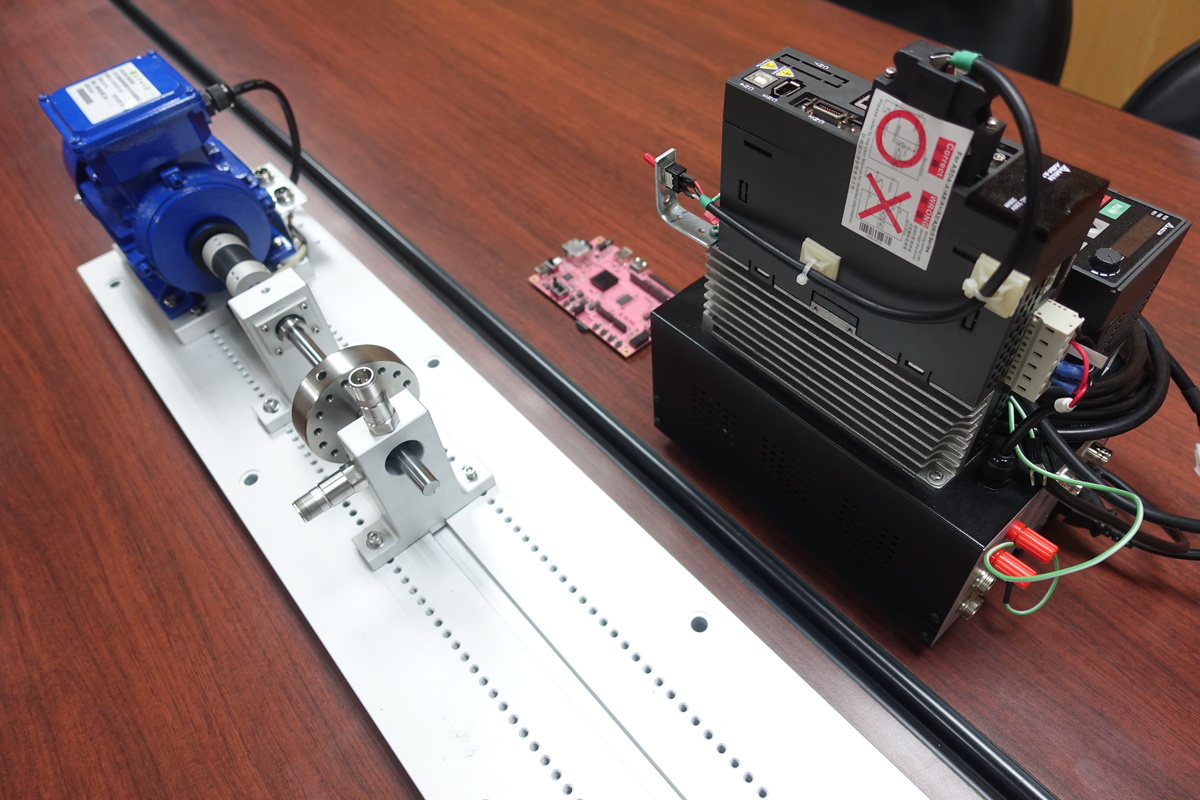

The bearing is used to support the shaft during the motor operation to leverage the high-speed rotation of the motor shaft and maintain the center position of the shaft. Any faulty parts in the bearing may bring many negative effects to the motor. The team explained the process of research and design. They inserted faulty bearings in the experiment and sent the collected signals, acquired by the vibration sensor, to the FPGA (Field Programmable Gate Array), equipped with AI hardware, for further AI computing. Finally, the results were outputted to computer software to determine the failure factors represented by different signals. The research and development results could effectively detect bearing faults. Professor Kun-Chih Chen, the advisor of the team, mentioned that it is common to output the hardware computing results to software for interpretation. In some complicated cases, such as the design of smartphones, wearable devices, etc., it is required to double confirm the computing results from hardware through high-precision software tools. The NSYSU team’s developed platform shows its accuracy clearly because of the consistent computing results from the software tools and the developed hardware platform.

Motor fault detection and diagnosis is a key technology for the electric vehicle industry. Because the high-speed wheel rolling in electric vehicle raises the bearing fault risk, the development of this diagnostic platform by the teacher and students in NSYSU can bring considerable benefits to the industry. In addition, motor-related industry fields, such as mass transportation systems (i.e., high-speed rail, MRT, etc.), wind-power industry, and smart factories are the target industries that may cooperate with the team and apply the developed technology in the future. Professor Chen said that AIoT technology has been applied to every aspect of human life and become one of the big waves in technology. NSYSU team will keep working for the technology development in the related fields and optimize the database to improve the performance of the diagnostic platform.

(Edited by Public Affairs Division)

AIoT is the combination of Artificial Intelligence technology and the Internet of Things in practical applications; it is a very popular trend at the moment. Three senior undergraduate students: Jo-Chiao Ku, Hsiang-Ling Tai, Jui-Cheng Wang, and a second-year Master student Jing-Wen Liang, designed the motor bearing fault detection system for the future smart factory under the guidance of Assistant Professor Kun-Chih Chen, and won the review committees’ favor. On the day of the finals, NSYSU students and teacher transported their work to the competition site for data analysis as well as a demonstration. To meet the requirements of this competition, they further designed a program to remove the noise in the acquired signals. The team immersed in their project wholeheartedly and usually stayed in the laboratory until early morning hours to collect data. Jui-Cheng Wang said very humbly that it is very surprising and unbelievable to hear the news of their victory. Jing-Wen Liang confidently mentioned that their developed platform fits in the trends of the modern smart industry. It can be widely used to find the bearing faults through signal collection and analysis, which will efficiently help the factory save labor expenses.

The bearing is used to support the shaft during the motor operation to leverage the high-speed rotation of the motor shaft and maintain the center position of the shaft. Any faulty parts in the bearing may bring many negative effects to the motor. The team explained the process of research and design. They inserted faulty bearings in the experiment and sent the collected signals, acquired by the vibration sensor, to the FPGA (Field Programmable Gate Array), equipped with AI hardware, for further AI computing. Finally, the results were outputted to computer software to determine the failure factors represented by different signals. The research and development results could effectively detect bearing faults. Professor Kun-Chih Chen, the advisor of the team, mentioned that it is common to output the hardware computing results to software for interpretation. In some complicated cases, such as the design of smartphones, wearable devices, etc., it is required to double confirm the computing results from hardware through high-precision software tools. The NSYSU team’s developed platform shows its accuracy clearly because of the consistent computing results from the software tools and the developed hardware platform.

Motor fault detection and diagnosis is a key technology for the electric vehicle industry. Because the high-speed wheel rolling in electric vehicle raises the bearing fault risk, the development of this diagnostic platform by the teacher and students in NSYSU can bring considerable benefits to the industry. In addition, motor-related industry fields, such as mass transportation systems (i.e., high-speed rail, MRT, etc.), wind-power industry, and smart factories are the target industries that may cooperate with the team and apply the developed technology in the future. Professor Chen said that AIoT technology has been applied to every aspect of human life and become one of the big waves in technology. NSYSU team will keep working for the technology development in the related fields and optimize the database to improve the performance of the diagnostic platform.

(Edited by Public Affairs Division)

Click Num:

Share