NSYSU and NTUST research to catalyze hydrogen economy

A team of NSYSU and National Taiwan University of Science and Technology (NTUST) researchers discovered that the photoelectrocatalytic reaction on the surface of BiVO4 (bismuth vanadate) turns glycerol – a by-product of the biodiesel industry, into dihydroxyacetone – a product with high economic value. In that process, the water molecules in the aqueous glycerol solution are broken down to hydrogen – a green and sustainable energy carrier, and oxygen. The results of their research, crucial for the biodiesel industry, were published in a top international journal – Applied Catalysis B Environmental.

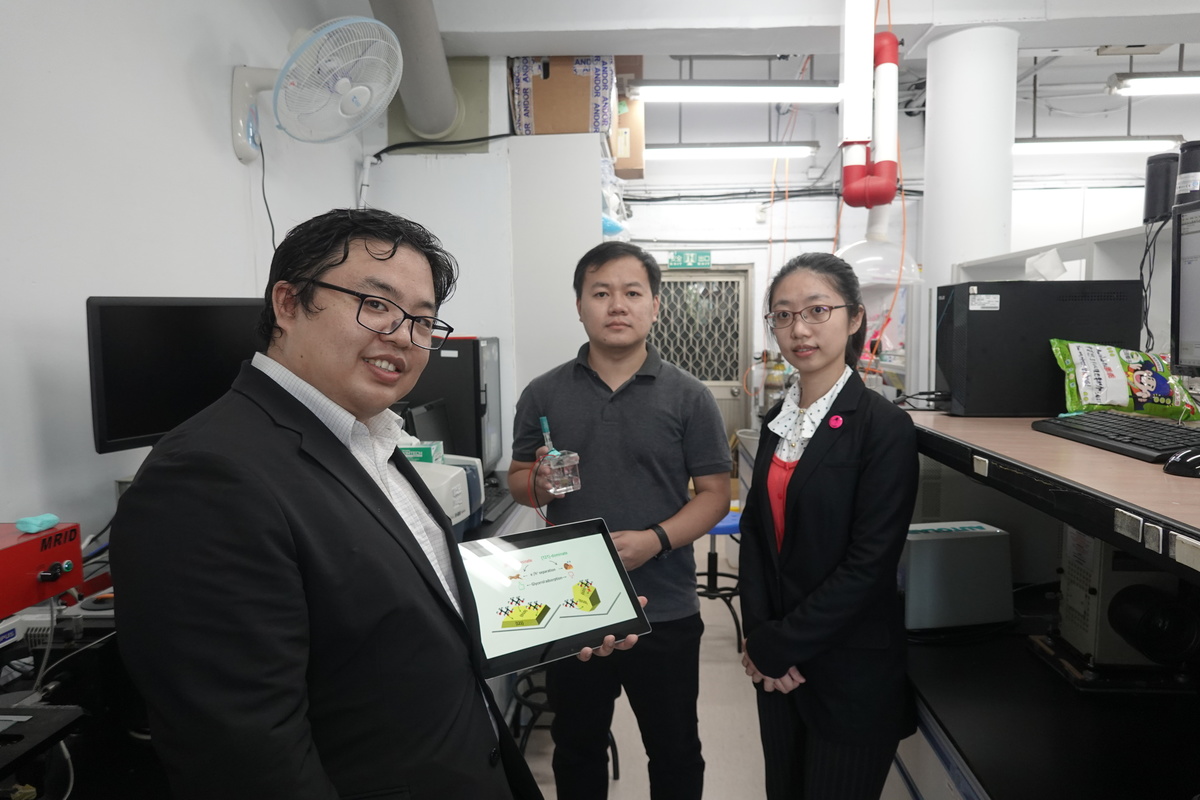

This research was conducted by the team led by Assistant Professor Cheng-chau Chiu of the Department of Chemistry at NSYSU and Associate Professor Chia-Ying Chiang of the Department of Chemical Engineering at NTUST. Its members included postdoctoral researcher from Vietnam Dr. Truong-Giang Vo and Master student Chi-Chang Kao of the Department of Chemical Engineering, NTUST. Applied Catalysis B Environmental, published by Elsevier, is one of the 5% most impactful journals worldwide in the field of physical chemistry and chemical engineering. It publishes highly innovative and prospective research on catalysis and its applications to solve environmental problems.

Reduction of the dependency on fossil fuels, alleviation of global warming and environmental problems, as well as the development of clean and renewable energy sources have become important research topics. In this context, hydrogen, obtained from water, is being discussed as a new energy source with considerable potential to replace fossil fuels. Another sustainable form of energy – biodiesel is attracting attention as well. Large quantities of glycerol are produced in the biodiesel industry. If glycerol can be turned into a product of high economic value, the biodiesel industry will become more profitable. This will also contribute to a cleaner, eco-friendlier, and more sustainable development.

About 90% of the products of the global chemical industry, which correspond to a value of around 900 billion USD per year, are obtained from catalytic processes. Assistant Professor Cheng-chau Chiu of NSYSU pointed out that in the team found significant differences in the catalytic performance between BiVO4 nanoparticles exposing different crystal surfaces. Using quantum mechanical density functional theory simulations, the team studied the different facets of BiVO4 and their interactions with the reactant glycerol at atomic level. This technique also allows one to find the crystal surfaces of BiVO4 with the best catalytic performance and thus maximizing the glycerol conversion efficiency.

Associate Professor of NTUST Chia-Ying Chiang said that in the past, cooperation between NTUST and the Tokyo Institute of Technology applied cuprous oxide as a catalyst and succeeded in turning glycerol into the high-value product dihydroxyacetone. This time, in collaboration with NSYSU, the team exploited the light-adsorbing properties of BiVO4 to conduct the catalytic conversion of glycerol. This allowed the successful production of dihydroxyacetone at reduced consumption of electrical energy.

Article in Science Direct:

https://www.sciencedirect.com/science/article/pii/S0926337320307189

This research was conducted by the team led by Assistant Professor Cheng-chau Chiu of the Department of Chemistry at NSYSU and Associate Professor Chia-Ying Chiang of the Department of Chemical Engineering at NTUST. Its members included postdoctoral researcher from Vietnam Dr. Truong-Giang Vo and Master student Chi-Chang Kao of the Department of Chemical Engineering, NTUST. Applied Catalysis B Environmental, published by Elsevier, is one of the 5% most impactful journals worldwide in the field of physical chemistry and chemical engineering. It publishes highly innovative and prospective research on catalysis and its applications to solve environmental problems.

Reduction of the dependency on fossil fuels, alleviation of global warming and environmental problems, as well as the development of clean and renewable energy sources have become important research topics. In this context, hydrogen, obtained from water, is being discussed as a new energy source with considerable potential to replace fossil fuels. Another sustainable form of energy – biodiesel is attracting attention as well. Large quantities of glycerol are produced in the biodiesel industry. If glycerol can be turned into a product of high economic value, the biodiesel industry will become more profitable. This will also contribute to a cleaner, eco-friendlier, and more sustainable development.

About 90% of the products of the global chemical industry, which correspond to a value of around 900 billion USD per year, are obtained from catalytic processes. Assistant Professor Cheng-chau Chiu of NSYSU pointed out that in the team found significant differences in the catalytic performance between BiVO4 nanoparticles exposing different crystal surfaces. Using quantum mechanical density functional theory simulations, the team studied the different facets of BiVO4 and their interactions with the reactant glycerol at atomic level. This technique also allows one to find the crystal surfaces of BiVO4 with the best catalytic performance and thus maximizing the glycerol conversion efficiency.

Associate Professor of NTUST Chia-Ying Chiang said that in the past, cooperation between NTUST and the Tokyo Institute of Technology applied cuprous oxide as a catalyst and succeeded in turning glycerol into the high-value product dihydroxyacetone. This time, in collaboration with NSYSU, the team exploited the light-adsorbing properties of BiVO4 to conduct the catalytic conversion of glycerol. This allowed the successful production of dihydroxyacetone at reduced consumption of electrical energy.

Article in Science Direct:

https://www.sciencedirect.com/science/article/pii/S0926337320307189

Click Num:

Share