Breakthrough in hydrogen energy: NSYSU awarded 5 international-level invention awards

2022-01-03

A global consensus to reduce carbon emissions has been reached to fight against extreme climate events. Hydrogen generated from green electricity-powered water electrolysis has been the main focus of research around the world. Professor Chun-Hu Chen of the Department of Chemistry at NSYSU led a research team to achieve a breakthrough in the industrial production of hydrogen energy and high-resolution electronic wire technology. These innovations have won five international-level awards across Europe and America, including gold and silver medals at America's Science & Invention Expo (ASIE) 2021, the Canadian Special Award, and the gold and silver medals at the International Warsaw Invention Show 2021.

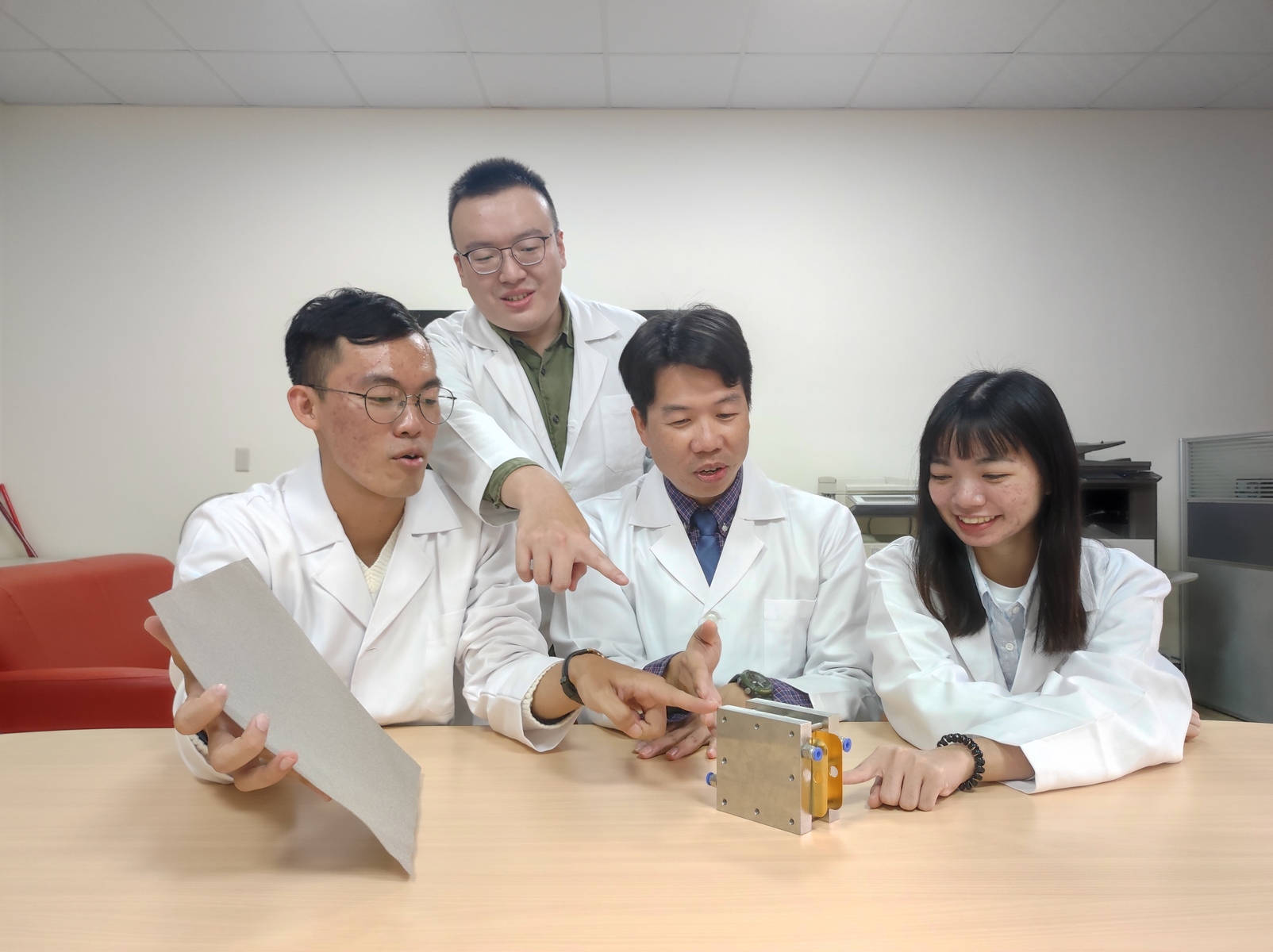

Professor Chun-Hu Chen pointed out that the main technical bottleneck at present is to achieve high current, large-scale hydrogen generation from water electrolysis. Most of the newest reports can only achieve a current density of 10-500 (mA cm-2). His research team, including graduate students Po-Jen Huang, Wen-Tai Chen, Wan-Yun Hsu, and Chun-Cheng Hsu, has successfully developed a high-adhesion catalyst for the oxygen evolution reaction that can overcome catalyst from peeling off under high current operation, thus achieving a continuous operation of the device at 5000 (mA cm-2), which is 10 to 500 times higher than the current standards. Its overall performance is also better than that of the current European commercial models.

“To neutralize carbon emissions and green energy storage, water electrolysis technology will need to reach high-current output in order to supply sufficient quantity of hydrogen” Professor Chun-Hu Chen said. The unique Acidic Redox-assisted Deposition (ARD) technology, developed by the NSYSU team, allows the mass production of key high-adhesion catalysts through roll-to-roll process, and uses common metal elements instead of relying on precious, rare-earth metals. This technology thus allows a significant reduction of the cost of hydrogen production for future commercial needs.

In addition, electronic components from today's 5G communications to next-generation rely on metal circuit technology that needs a continuing increase in resolution and density. Today's screen printing process is limited to a resolution of approximately 100 microns, and cannot meet the present resolution requirements for line width/wire intervals of below 40 microns. Professor Chun-Hu Chen led his graduate students Chia-Chun Hsieh, Yi-Cheng Chou, and Wei-Renn Tang, as well as established an industry-academia cooperation with Ample Electronic Technology, and successfully developed photolithographic silver pastes. These silver pastes can quickly produce high-resolution metallic line patterns in just three steps: coating, light exposure, and development. The resolution can be significantly improved in comparison to conventional processes, to an optimal resolution of 5-micron line width / 13-micron line spacing. This technology obtained the silver medal at America's Science & Invention EXPO (ASIE) 2021, the silver medal at the International Warsaw Invention Show 2021, and the FUTEX Future Tech Award by the Ministry of Science and Technology.

Professor Chun-Hu Chen will continue to work with his team to promote the application of these two technologies through technology transfer and patenting. Under further collaboration with Taiwan's industry, government agencies, academia, and research institutions to push up technological boundaries, Taiwan could establish self-sufficient technologies in green energy. Professor Chen hopes to make NSYSU become an important base for the development of green energy.

A global consensus to reduce carbon emissions has been reached to fight against extreme climate events. Hydrogen generated from green electricity-powered water electrolysis has been the main focus of research around the world. Professor Chun-Hu Chen of the Department of Chemistry at NSYSU led a research team to achieve a breakthrough in the industrial production of hydrogen energy and high-resolution electronic wire technology. These innovations have won five international-level awards across Europe and America, including gold and silver medals at America's Science & Invention Expo (ASIE) 2021, the Canadian Special Award, and the gold and silver medals at the International Warsaw Invention Show 2021.

Professor Chun-Hu Chen pointed out that the main technical bottleneck at present is to achieve high current, large-scale hydrogen generation from water electrolysis. Most of the newest reports can only achieve a current density of 10-500 (mA cm-2). His research team, including graduate students Po-Jen Huang, Wen-Tai Chen, Wan-Yun Hsu, and Chun-Cheng Hsu, has successfully developed a high-adhesion catalyst for the oxygen evolution reaction that can overcome catalyst from peeling off under high current operation, thus achieving a continuous operation of the device at 5000 (mA cm-2), which is 10 to 500 times higher than the current standards. Its overall performance is also better than that of the current European commercial models.

“To neutralize carbon emissions and green energy storage, water electrolysis technology will need to reach high-current output in order to supply sufficient quantity of hydrogen” Professor Chun-Hu Chen said. The unique Acidic Redox-assisted Deposition (ARD) technology, developed by the NSYSU team, allows the mass production of key high-adhesion catalysts through roll-to-roll process, and uses common metal elements instead of relying on precious, rare-earth metals. This technology thus allows a significant reduction of the cost of hydrogen production for future commercial needs.

In addition, electronic components from today's 5G communications to next-generation rely on metal circuit technology that needs a continuing increase in resolution and density. Today's screen printing process is limited to a resolution of approximately 100 microns, and cannot meet the present resolution requirements for line width/wire intervals of below 40 microns. Professor Chun-Hu Chen led his graduate students Chia-Chun Hsieh, Yi-Cheng Chou, and Wei-Renn Tang, as well as established an industry-academia cooperation with Ample Electronic Technology, and successfully developed photolithographic silver pastes. These silver pastes can quickly produce high-resolution metallic line patterns in just three steps: coating, light exposure, and development. The resolution can be significantly improved in comparison to conventional processes, to an optimal resolution of 5-micron line width / 13-micron line spacing. This technology obtained the silver medal at America's Science & Invention EXPO (ASIE) 2021, the silver medal at the International Warsaw Invention Show 2021, and the FUTEX Future Tech Award by the Ministry of Science and Technology.

Professor Chun-Hu Chen will continue to work with his team to promote the application of these two technologies through technology transfer and patenting. Under further collaboration with Taiwan's industry, government agencies, academia, and research institutions to push up technological boundaries, Taiwan could establish self-sufficient technologies in green energy. Professor Chen hopes to make NSYSU become an important base for the development of green energy.

Click Num:

Share