NSYSU’s original Supercritical Fluid technology landed investment from Japan’s leading semiconductor manufacturer

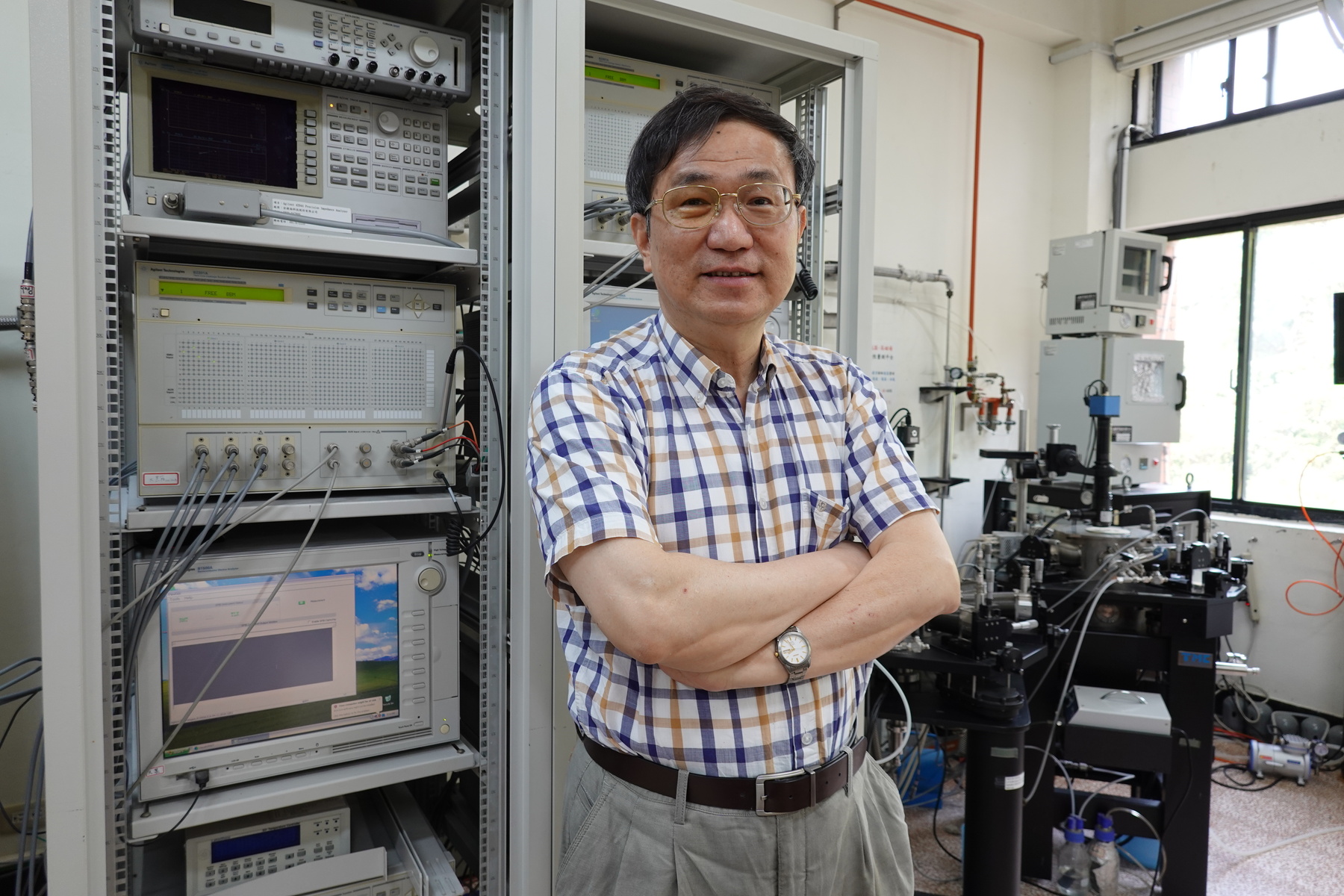

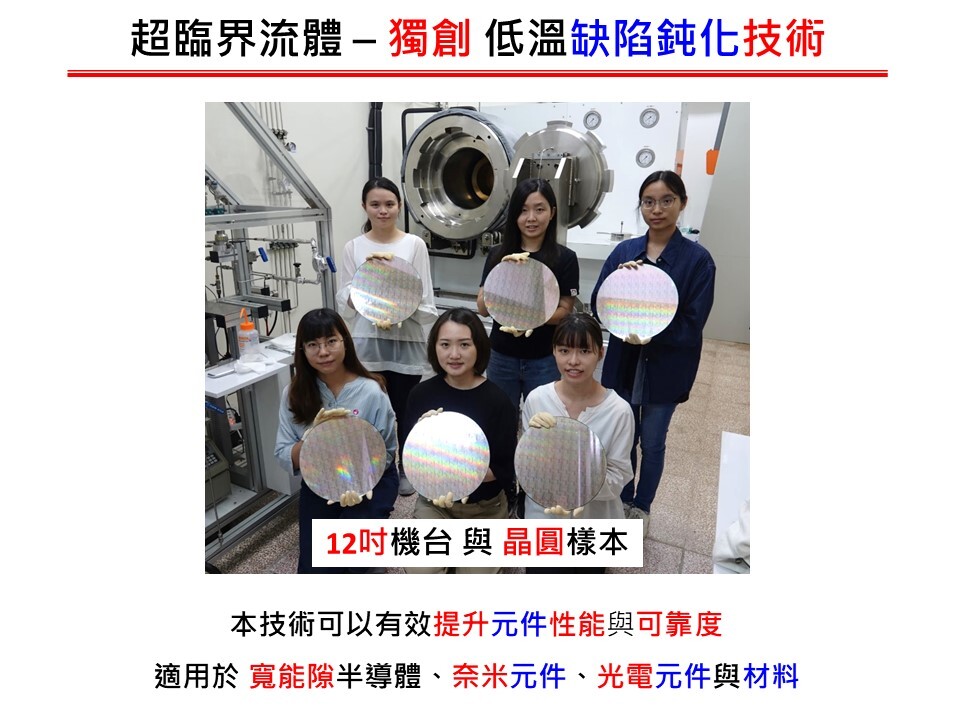

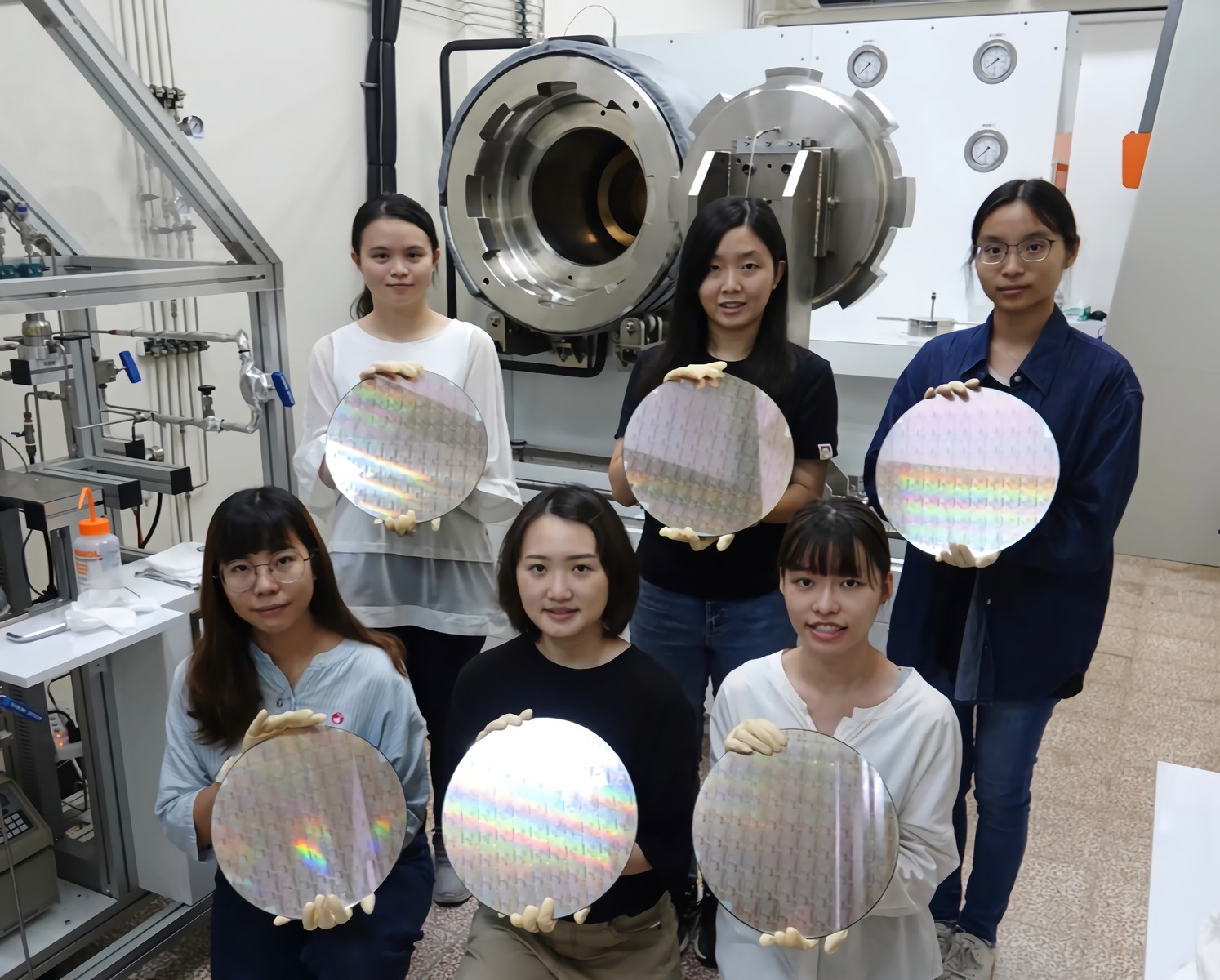

NSYSU’s research team of the Department of Physics has made significant progress to pursue higher yield in semiconductor fabrication. The original technology, Supercritical Fluid Low Temperature Defect Passivation, developed by the distinguished chair professor Ting-Chang Chang, has raised much awareness in the industry. Naidun-tech, the company founded by Prof. Chang’s team is the first start-up company in Taiwan funded by Tokyo Electron, Japan’s leading semiconductor equipment manufacturer. In Taiwan, Naidun-tech has obtained investments from AU Optronics and Taiwan Germination Program by Ministry of Science and Technology.

“Supercritical fluid is defined as a certain state of matter: As solid is heated, it turns into liquid, and heated liquid turns into gas. If the temperature and pressure of gas is continuously increased, it turns into the state of above critical temperature and pressure where gases and liquids can coexist. The state is named supercritical fluid.” Says Prof. Chang. Due to its strong permeability and solubility, supercritical fluid is commonly used in the extraction process to manufacture skin-care products, cleansers, supplements or products with extracted caffeine etc.

“We use the supercritical fluids techniques in an uncommon way, though, to introduce new materials.” Prof. Chang says, “As the geometry of transistors in the semiconductor constantly shrinks, the etching and film deposition process might introduce a lot of defects to the devices. Current technologies are not good solutions to these defects.” Prof.Chang emphasized that supercritical fluid, as the state where gas and liquid coexist, can be applied to remove defects in the electronic devices, increase functionality and reliability through its high reactivity, high permeability and low surface tension.

What makes an electronic product competitive are all about functionality and reliability of its devices. However, dangling bonds are constantly formed at the interface of different materials inside the devices during the manufacturing process. Those are internal defects that impact the yield. For example, defects at the sidewalls of a Micro LED device are constantly inspected, which significantly reduce the emitting efficiency. The common method to passivate (reduce) the defects is heat activation. However, heat activation can’t be used in metal materials. In the process of passivation, temperature is usually increased to 800 Celsius, while the devices with metals can usually withstand no more than 400 Celsius. With this limitation, the heat passivation can hardly be used to solve the defect problem.

“However, with the Supercritical Fluid Low Temperature Defect Passivation technology, the temperature requirements can be lowered to 200-300 Celsius.” Prof. Chang emphasized. “By using this technology to repair the broken bond inside the semiconductor materials, we can restore the bad devices, improving the leakage current and conductivities. This new technology can meet the requirement that can’t be done by old technologies, and be applied to many types of devices like FinFET, LED, optoelectronics, even wide bandgap semiconductors(SiC、GaN).”

“The Department of Physics team had spent 15 years to study supercritical fluid, with enthusiasm of exploring the unknown of science. Founding Naidun-tech is like an unexpected turning point.”

Through the effort of exploring, the team has found supercritical fluid’s applicability of engineering, and proved it by experiments on many kinds of devices. The industrialization of this technology are actually being carried out. “It means that our study is noted and appreciated.” Says Prof. Chang.

In addition to the competency of the technology, it takes experienced managerial specialists to help a start-up company successfully land high-profile investors. Naidun-tech team is currently composed by members with years of industry experiences, including his former students. They are all passionate with the company’s vision: to industrialize the technical innovations from laboratory, and apply it to enhance the industry.

“The starting point seems inspiring, that we built a start-up and it’s actually funded. However, we still have tons of works to do and there’s no visible terminal point.” Says Prof. Chang.

“Supercritical fluid is defined as a certain state of matter: As solid is heated, it turns into liquid, and heated liquid turns into gas. If the temperature and pressure of gas is continuously increased, it turns into the state of above critical temperature and pressure where gases and liquids can coexist. The state is named supercritical fluid.” Says Prof. Chang. Due to its strong permeability and solubility, supercritical fluid is commonly used in the extraction process to manufacture skin-care products, cleansers, supplements or products with extracted caffeine etc.

“We use the supercritical fluids techniques in an uncommon way, though, to introduce new materials.” Prof. Chang says, “As the geometry of transistors in the semiconductor constantly shrinks, the etching and film deposition process might introduce a lot of defects to the devices. Current technologies are not good solutions to these defects.” Prof.Chang emphasized that supercritical fluid, as the state where gas and liquid coexist, can be applied to remove defects in the electronic devices, increase functionality and reliability through its high reactivity, high permeability and low surface tension.

What makes an electronic product competitive are all about functionality and reliability of its devices. However, dangling bonds are constantly formed at the interface of different materials inside the devices during the manufacturing process. Those are internal defects that impact the yield. For example, defects at the sidewalls of a Micro LED device are constantly inspected, which significantly reduce the emitting efficiency. The common method to passivate (reduce) the defects is heat activation. However, heat activation can’t be used in metal materials. In the process of passivation, temperature is usually increased to 800 Celsius, while the devices with metals can usually withstand no more than 400 Celsius. With this limitation, the heat passivation can hardly be used to solve the defect problem.

“However, with the Supercritical Fluid Low Temperature Defect Passivation technology, the temperature requirements can be lowered to 200-300 Celsius.” Prof. Chang emphasized. “By using this technology to repair the broken bond inside the semiconductor materials, we can restore the bad devices, improving the leakage current and conductivities. This new technology can meet the requirement that can’t be done by old technologies, and be applied to many types of devices like FinFET, LED, optoelectronics, even wide bandgap semiconductors(SiC、GaN).”

“The Department of Physics team had spent 15 years to study supercritical fluid, with enthusiasm of exploring the unknown of science. Founding Naidun-tech is like an unexpected turning point.”

Through the effort of exploring, the team has found supercritical fluid’s applicability of engineering, and proved it by experiments on many kinds of devices. The industrialization of this technology are actually being carried out. “It means that our study is noted and appreciated.” Says Prof. Chang.

In addition to the competency of the technology, it takes experienced managerial specialists to help a start-up company successfully land high-profile investors. Naidun-tech team is currently composed by members with years of industry experiences, including his former students. They are all passionate with the company’s vision: to industrialize the technical innovations from laboratory, and apply it to enhance the industry.

“The starting point seems inspiring, that we built a start-up and it’s actually funded. However, we still have tons of works to do and there’s no visible terminal point.” Says Prof. Chang.

Click Num:

Share