NSYSU unveiled the world's first prototype of seawater hydrogen production, breaking through the key technology of mass production of green hydrogen

2024-09-03

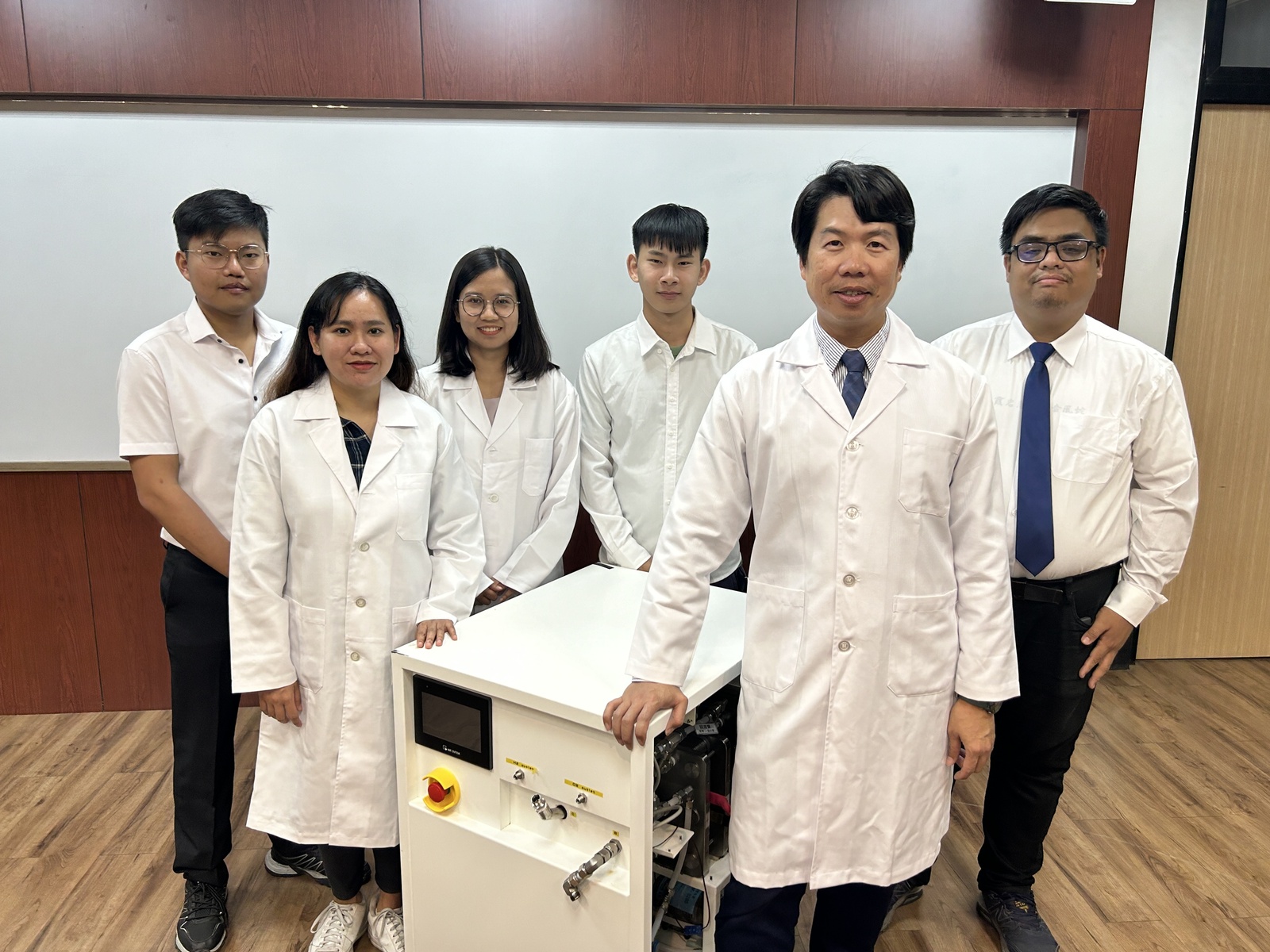

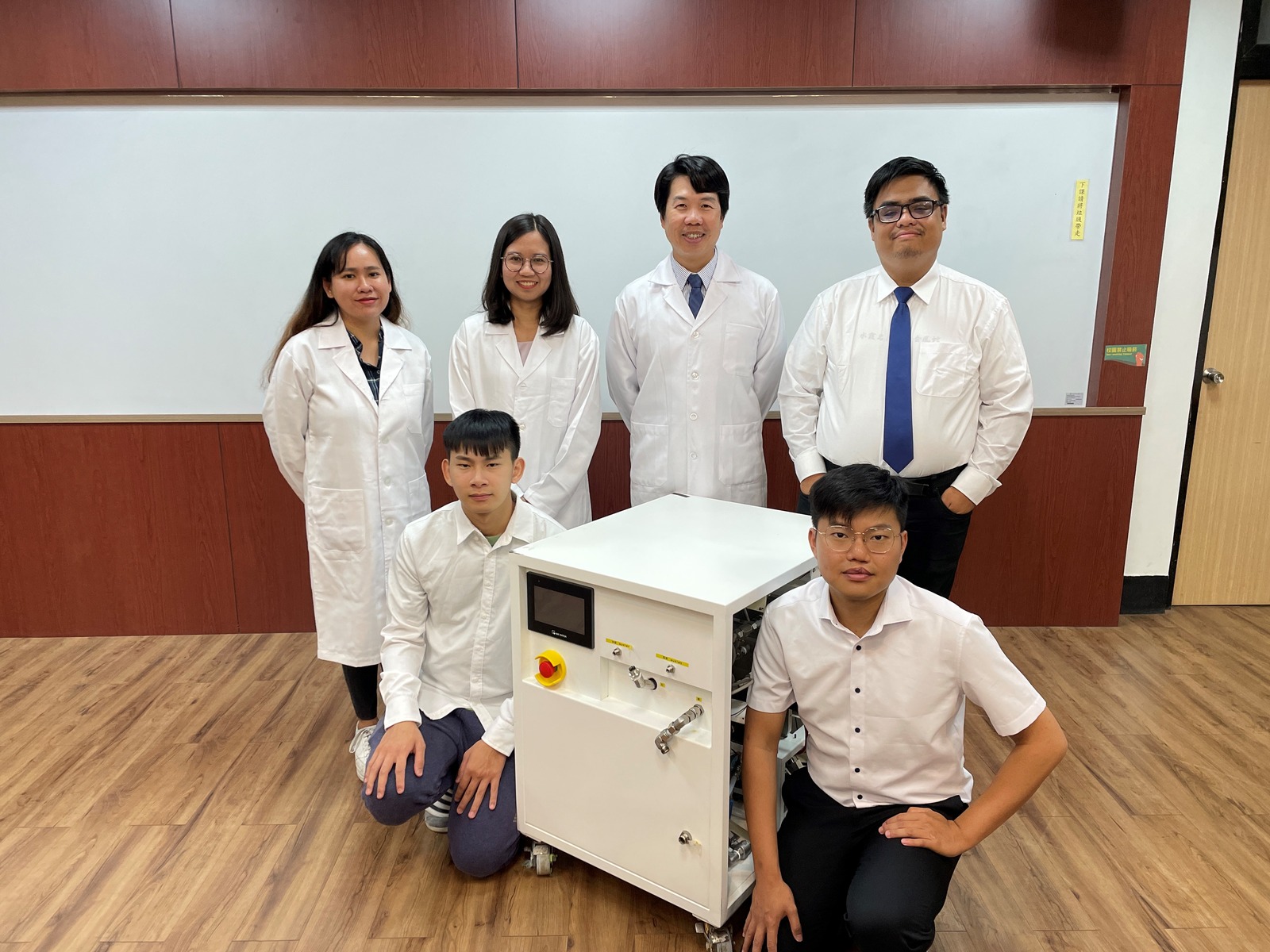

With the 2025 international carbon tax imminent, the research team led by Chun-Hu Chen, a Distinguished Professor of the Department of Chemistry at National Sun Yat-sen University (NSYSU), has mastered key technologies and launched the world's first prototype of "alkaline seawater electrolyzer for hydrogen production." This unique green hydrogen technology is unprecedented and expected for large-scale mass production, making Kaohsiung's Sizihwan Bay the origin of electrolysis seawater hydrogen production cutting-edge technology.

The research team pointed out that to pursue net-zero emissions in 2050, developing clean and renewable alternative energy sources is urgent. Among them, using green electricity, such as solar energy and wind power, by electrolysis water to produce hydrogen (also known as green hydrogen) is a powerful tool for reducing carbon emissions and storing energy. Current industrial activities urgently require hydrogen as a raw material, such as a raw material for making ammonia, hydrogen peroxide and methanol, rocket fuel, and a reducing agent when refining metals. Compared with other renewable energy sources of electricity, hydrogen can preserve green energy more effectively. Therefore, hydrogen production by water electrolysis is regarded as the most promising new opportunity for large-scale mass production of hydrogen with green energy.

According to the 2023 International Energy Agency (IEA) report, the proportion of global green hydrogen production capacity has only gradually climbed to 0.7% from 0.1% in 2018. There are still many thresholds to overcome. One of the biggest difficulties currently is the lack of prototype technology that can be mass-produced to verify the feasibility of future commercialization. Chun-Hu Chen pointed out that after years of technical accumulation, the research team recently unveiled the first prototype of alkaline seawater electrolyzer for hydrogen production, significantly exceeding the hydrogen production capacity of academic research levels. The prototype machine, measuring 70 cm in length, 60 cm in width, and 74 cm in height, is equipped with multiple water electrolytic components capable of producing hydrogen from seawater and general water bodies by water electrolysis. The maximum hydrogen production can be over a hundred times that of laboratory-grade components, establishing the feasibility of large-scale hydrogen production. Particularly for Taiwan, an island country, successfully utilizing seawater conversion for long-term hydrogen production could help gradually get rid of energy dependence on imports and avoid the risk of energy supply disruptions due to regional conflicts.

Chun-Hu Chen explained that the team can mass-produce catalysts under room temperature and pressure using the "roll-to-roll" method, recognized as the prototype of quasi-mass production technology in the industry, and can produce approximately 5m x 0.25m of catalyst per hour. This represents the opportunity to connect to an automated production line to obtain finished products at a lower cost and faster production speed. Referring to domestic and foreign literature and technology, producing a catalyst as small as 1cm x 1cm takes days. The multi-step process is more time-consuming and usually involves high temperature and pressure. The operating power of the team's prototype has exceeded the kilowatt level threshold for commercial basic requirements. It is also equipped with a wireless remote control human-machine interface and a safety device to prevent machine operation from idling. Responding to the demand for large-scale field deployment in the future, it lays a groundbreaking foundation for future large-scale seawater hydrogen production opportunities.

Chun-Hu Chen elaborated that the difficulties in large-scale seawater hydrogen production worldwide are roughly similar, with two main technical problems being the generation of toxic chlorine gas and seawater corrosion. The key lies in preventing the loss of core catalysts and resisting chemical corrosion from chlorine ions or their derivatives in seawater. "Large-scale water electrolysis puts enormous stripping pressure on catalysts, and without strong chemical bonding designs, even the most expensive and efficient catalysts or equipment will gradually fail." The team's unique "Acidic Redox-assisted Deposition (ARD)" technology is the key to solving this problem effectively and can currently produce more than 100 square centimeters of catalysts.

NSYSU stated that this research result has won numerous awards, including the 2023 Future Tech Award, the International Warsaw Invention Show (IWIS) 2021 Gold Medal, the 2021 America's Science and Invention Expo (ASIE) Gold Medal, and the 2021 Toronto International Society of Innovation & Advanced Skills (TISIAS) Special Award, establishing the high industrial value and leading position of ARD technology. The research team members include graduate student Ching-Hsiang Lin, doctoral candidate Yanita Devi, and senior technology development manager Yun-Pei Liu. This technology has long-term research and development funding support from the National Science and Technology Council, the National Academy of Marine Research, and other industrial organizations. It is hoped that more relevant government units and industries will invest in research and development and work together to achieve global clean energy and sustainable development goals.

With the 2025 international carbon tax imminent, the research team led by Chun-Hu Chen, a Distinguished Professor of the Department of Chemistry at National Sun Yat-sen University (NSYSU), has mastered key technologies and launched the world's first prototype of "alkaline seawater electrolyzer for hydrogen production." This unique green hydrogen technology is unprecedented and expected for large-scale mass production, making Kaohsiung's Sizihwan Bay the origin of electrolysis seawater hydrogen production cutting-edge technology.

The research team pointed out that to pursue net-zero emissions in 2050, developing clean and renewable alternative energy sources is urgent. Among them, using green electricity, such as solar energy and wind power, by electrolysis water to produce hydrogen (also known as green hydrogen) is a powerful tool for reducing carbon emissions and storing energy. Current industrial activities urgently require hydrogen as a raw material, such as a raw material for making ammonia, hydrogen peroxide and methanol, rocket fuel, and a reducing agent when refining metals. Compared with other renewable energy sources of electricity, hydrogen can preserve green energy more effectively. Therefore, hydrogen production by water electrolysis is regarded as the most promising new opportunity for large-scale mass production of hydrogen with green energy.

According to the 2023 International Energy Agency (IEA) report, the proportion of global green hydrogen production capacity has only gradually climbed to 0.7% from 0.1% in 2018. There are still many thresholds to overcome. One of the biggest difficulties currently is the lack of prototype technology that can be mass-produced to verify the feasibility of future commercialization. Chun-Hu Chen pointed out that after years of technical accumulation, the research team recently unveiled the first prototype of alkaline seawater electrolyzer for hydrogen production, significantly exceeding the hydrogen production capacity of academic research levels. The prototype machine, measuring 70 cm in length, 60 cm in width, and 74 cm in height, is equipped with multiple water electrolytic components capable of producing hydrogen from seawater and general water bodies by water electrolysis. The maximum hydrogen production can be over a hundred times that of laboratory-grade components, establishing the feasibility of large-scale hydrogen production. Particularly for Taiwan, an island country, successfully utilizing seawater conversion for long-term hydrogen production could help gradually get rid of energy dependence on imports and avoid the risk of energy supply disruptions due to regional conflicts.

Chun-Hu Chen explained that the team can mass-produce catalysts under room temperature and pressure using the "roll-to-roll" method, recognized as the prototype of quasi-mass production technology in the industry, and can produce approximately 5m x 0.25m of catalyst per hour. This represents the opportunity to connect to an automated production line to obtain finished products at a lower cost and faster production speed. Referring to domestic and foreign literature and technology, producing a catalyst as small as 1cm x 1cm takes days. The multi-step process is more time-consuming and usually involves high temperature and pressure. The operating power of the team's prototype has exceeded the kilowatt level threshold for commercial basic requirements. It is also equipped with a wireless remote control human-machine interface and a safety device to prevent machine operation from idling. Responding to the demand for large-scale field deployment in the future, it lays a groundbreaking foundation for future large-scale seawater hydrogen production opportunities.

Chun-Hu Chen elaborated that the difficulties in large-scale seawater hydrogen production worldwide are roughly similar, with two main technical problems being the generation of toxic chlorine gas and seawater corrosion. The key lies in preventing the loss of core catalysts and resisting chemical corrosion from chlorine ions or their derivatives in seawater. "Large-scale water electrolysis puts enormous stripping pressure on catalysts, and without strong chemical bonding designs, even the most expensive and efficient catalysts or equipment will gradually fail." The team's unique "Acidic Redox-assisted Deposition (ARD)" technology is the key to solving this problem effectively and can currently produce more than 100 square centimeters of catalysts.

NSYSU stated that this research result has won numerous awards, including the 2023 Future Tech Award, the International Warsaw Invention Show (IWIS) 2021 Gold Medal, the 2021 America's Science and Invention Expo (ASIE) Gold Medal, and the 2021 Toronto International Society of Innovation & Advanced Skills (TISIAS) Special Award, establishing the high industrial value and leading position of ARD technology. The research team members include graduate student Ching-Hsiang Lin, doctoral candidate Yanita Devi, and senior technology development manager Yun-Pei Liu. This technology has long-term research and development funding support from the National Science and Technology Council, the National Academy of Marine Research, and other industrial organizations. It is hoped that more relevant government units and industries will invest in research and development and work together to achieve global clean energy and sustainable development goals.

Click Num:

Share