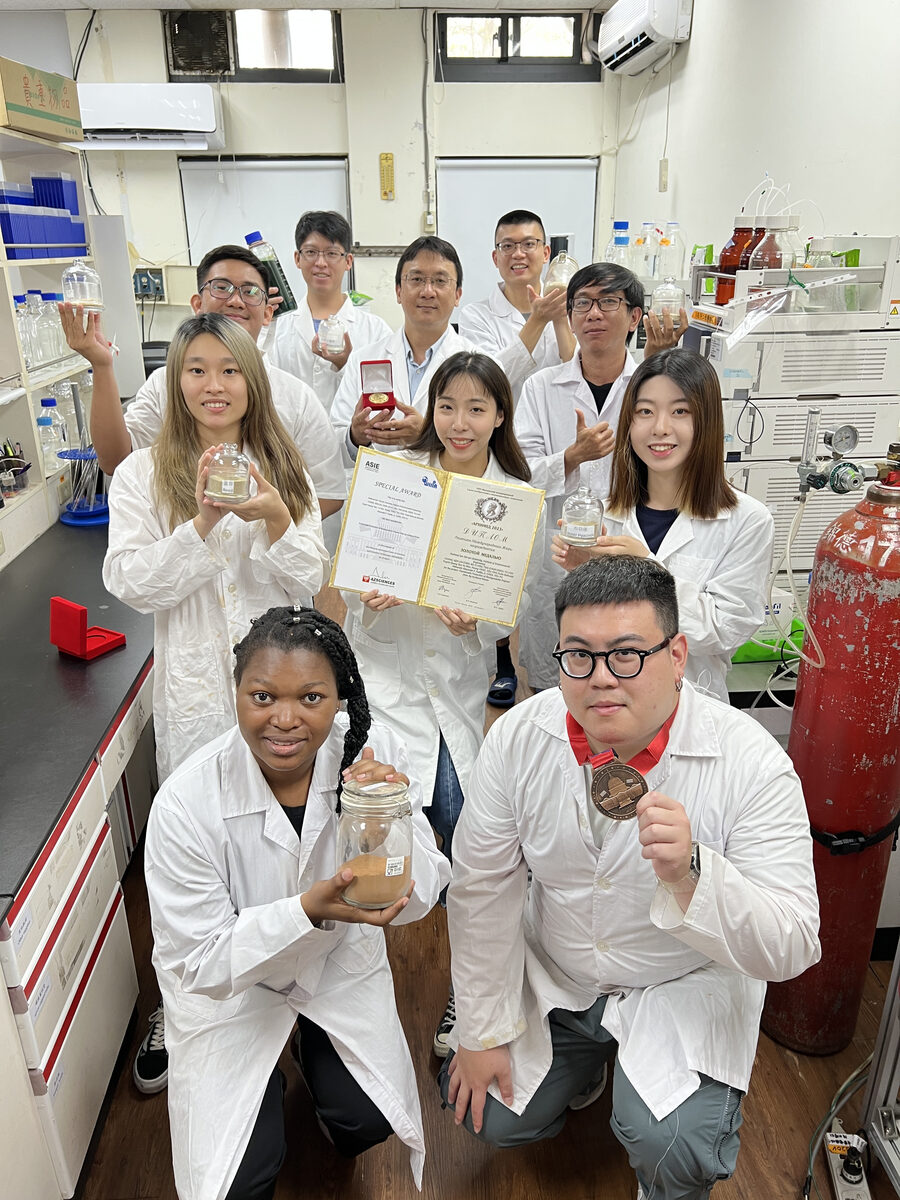

Ken-Lin Chang at NSYSU converted agricultural waste into green gold and won the gold medal at the international invention exhibition

2024-03-26

Associate Professor Ken-Lin Chang of the Institute of Environmental Engineering at National Sun Yat-sen University (NSYSU) and his team created an innovative approach to convert agricultural waste into chemical materials with a wide range of uses, effectively synthesizing 2, 5-furan dicarboxylic acid (FDCA), which can help alleviate plastic pollution and greenhouse effect. This research and development achievement won the gold medal at the Russia 2023 Moscow International Salon of Inventions and Innovation Technologies ARCHIMEDES and the Special Award from America’s Science & Invention Expo.

FDCA can be polymerized to produce Polyethylene 2, 5-furandicarboxylate (PEF), a new generation of biodegradable materials with superior properties. Its gas barrier and water barrier properties are 6 to 10 times higher than currently common PET materials on the market. Compared with preparing PET, using FDCA polymerization to produce PEF can reduce energy consumption by 51% to 58% and greenhouse gas emissions by about 60%, which has significant environmental advantages. It can also be used as an alternative resin for beverage bottles, and its film and fiber can also be used in food packaging, carpets, textiles, and other applications. It has attracted the interest of major global companies such as Coca-Cola, Danone Group, ALPLA, and Carlsberg, and the prospects are promising.

Ken-Lin Chang said that FDCA can be used in many different fields. However, current production requires expensive raw materials, catalysts, and strict condition control, preventing the widespread use in large-scale mass production. There is an urgent need to find a process that is efficient, simple, and can reduce costs. To this end, the research team developed an innovative process that uses agricultural waste such as rice straw, bagasse, pineapple stem, and jackfruit peel as reaction raw materials through a new simple technology, the "one-pot and two steps" reaction, directly converts the biomass waste materials. This technology uses a low-cost chemical reaction system to reduce waste generation. It is not only efficient, simple, and economical but also aligns with various green chemistry principles and the United Nations Sustainable Development Goals (SDGs) concepts, making a significant contribution to the fields of pollution control and environmental protection.

Ken-Lin Chang's research team further explained the manufacturing process. Agricultural waste and other biomass are heated in an oil bath at 150°C for 120 minutes with Dimethyl Sulfoxide (DMSO), betaine hydrochloride (BHC), and AlCl3·6H2O to convert them into 5-Hydroxymethylfurfural (5-HMF). After that, under continual stirring, the oxidation reaction was carried out in an oil bath at 80°C for 12 hours using Cu-MnO2 as the catalyst and tert-butyl hydroperoxide (tBuOOH) as an oxidant. Finally, 70% HMF and 77% FDCA can be obtained.

This new product that turns agricultural waste into green gold is not only recognized as one of 12 priority biomass-based chemicals by the U.S. Department of Energy but is also known as a "sleeping giant," playing a key role in establishing the green chemical industry of the future. Its ingredients help extinguish fires in a short time and can be used as fire foams; its anti-bacterial properties and strong anesthetic actions can be used in the pharmacology field; it can also prepare various polymers such as polyester, polyurethane, polyamide, etc.; it can be a substitute for phthalate plasticizers used to produce PVC or as a precursor to levulinic acid and succinic acid. Companies such as Coca-Cola and DuPont in the United States, BASF in Germany, Mitsubishi in Japan, and Avantium in the Netherlands all regard the commercialization of FDCA copolyester as a critical development product in the current market.