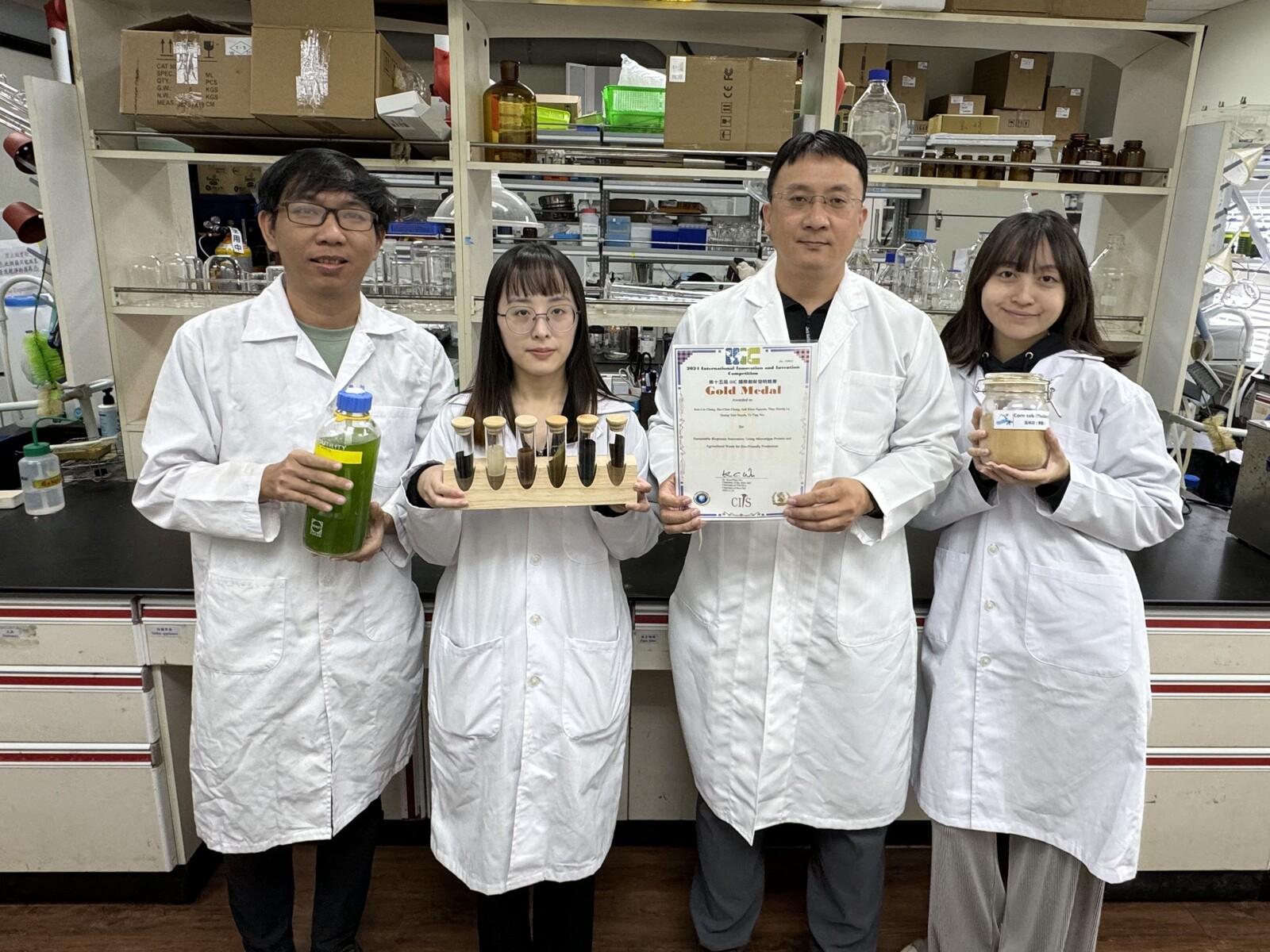

Microalgae and agricultural waste transformed into eco-friendly carbon-reducing plastic – NSYSU wins international invention gold medal

2025-05-20

Agricultural waste can also be transformed into eco-friendly, carbon-reducing plastics! Professor Ken-Lin Chang from the Institute of Environmental Engineering at National Sun Yat-sen University (NSYSU) led a research team to develop eco-friendly, carbon-reducing bioplastics using marine microalgae and agricultural waste. After optimizing the process, they were able to extract microalgae protein within 8 minutes and utilized discarded banana pseudo-stems to enhance the tensile strength and elongation of bioplastic films, demonstrating excellent application performance. This innovative technology promotes a sustainable circular economy and creates new added value for the agricultural industry. The achievement was awarded the Gold Medal at the 15th IIIC International Innovation and Invention Competition. Additionally, Professor Ken-Lin Chang also honored with the 20th International Inventor Prize for his long-term dedication to developing eco-friendly plastics reduction, agricultural waste reutilization, and carbon dioxide (CO2) conversion technologies.

The 15th IIIC International Innovation and Invention Competition focused on environmental preservation, covering four primary themes: energy efficiency, carbon reduction, biotechnology, and intelligent living. The competition featured over 447 outstanding inventions from 12 different countries, including Taiwan, Japan, Malaysia, China, Singapore, Thailand, the United States, Russia, Morocco, Peru, Ecuador, and Spain. The 20th International Inventor Prize is awarded to individuals who have previously won prestigious international invention competitions or science contests and have passed a rigorous selection process, with only five recipients chosen.

Professor Chang emphasized that the world is facing a severe plastic pollution crisis, with approximately 38 million tons of plastic waste entering the ocean annually, making sustainable solutions more urgent than ever. Compared to traditional plastics, the team's eco-friendly carbon-reducing bioplastics offer multiple benefits: they have a lower carbon footprint, utilize renewable resources, and are biodegradable. Chang highlighted that using banana pseudo-stems for bioplastic production not only reduces agricultural waste but also stimulates rural economies. Meanwhile, marine microalgae have diverse applications in pharmaceuticals, bioplastics, cosmetics, food, and animal feed, making them essential to both ecological and industrial advancements. The innovative combination of these two raw materials for sustainable bioplastic alternatives holds immense potential for replacing conventional plastics and advancing sustainable development.

Further explaining the research, Chang noted that the biodegradable, carbon-reducing plastic is made from microalgae protein extracted through a novel, scalable method. The team developed an effective microalgae protein extraction process using an ultrasonic homogenizer in a buffer solution containing potassium hydroxide (KOH), potassium chloride (KCl), and glycerol. By optimizing the process through Response Surface Methodology (RSM), the team determined the ideal conditions: 14 mL of solution, an 8-minute treatment time, and a pH of 10.5, achieving a 73.38% extraction efficiency and 86.45% protein purity.

To enhance the mechanical properties of the bioplastic film, various fillers were tested. The study found that incorporating banana pseudo-stem powder as a filler resulted in a tensile strength of 7.08 MPa and an elongation rate of 15.60%, demonstrating the value-added potential of agricultural waste. Given that microalgae are easy to cultivate with rapid growth, and agricultural waste is eco-friendly and cost-effective, the resulting bioplastic presents a highly viable alternative to traditional plastics, attracting significant attention from industry stakeholders.